Video: Startup Coffee Company Has Engineering Roots at Georgia Tech

Samuel Graham Named to Georgia Tech Presidential Search Committee

Samuel Graham, the Eugene C. Gwaltney Jr. School Chair, George W. Woodruff School of Mechanical Engineering, has been named to the Georgia Institute of Technology Presidential Search Committee which will conduct a national search to replace Georgia Tech President G.P. “Bud” Peterson, who will retire as president this summer. Dr. Graham earned his M.S. and Ph. D. at Georgia Tech, has been a member of the faculty since 2003, and became chair of the Woodruff School on July 1, 2018.

Woodruff School alumnus Thomas E. Noonan ('83) was also named to the committee. Mr. Noonan is the chairman of TEN Holdings LLC.

Georgia Tech Press Release

The Board of Regents of the University System of Georgia (USG) today named members of the Georgia Institute of Technology Presidential Search Committee. The committee will conduct a national search to replace Georgia Tech President G.P. “Bud” Peterson, who will retire as president this summer.

- Regent Ben J. Tarbutton III, committee chair

- Regent C. Dean Alford

- Regent Laura Marsh

- Regent Sarah-Elizabeth Reed

- Regent Sachin Shailendra

- Regent Thomas Rogers Wade

- Regent Don L. Waters, chairman, Board of Regents

- Joeleen Akin, associate athletic director, Georgia Tech Athletic Association

- Richard Barke, Ph.D., associate professor and director of undergraduate studies, School of Public Policy, Ivan Allen College of Liberal Arts

- Nisha D. Botchwey, Ph.D. associate professor, School of City and Regional Planning, College of Design

- John F. Brock III, CEO, Coca-Cola European Partners (retired); chair, Brock Holdings LLC

- David Brown, Facilities Infrastructure and Power Plant; chair, Georgia Tech Staff Council

- Andrew Cox, president, Graduate Student Government Association

- Evan Gillon, president, Undergraduate Student Government Association

- Samuel Graham, Ph.D., chair, Woodruff School of Mechanical Engineering, College of Engineering

- Joseph L. A. Hughes, Ph.D., professor, School of Electrical & Computer Engineering, College of Engineering; chair, Faculty Executive Board

- Charles Isbell Jr., Ph.D., professor and executive associate dean, College of Computing

- Michelle Jarrard, senior partner (retired), McKinsey & Company; board member, Lazard Inc., board member, Crawford & Company

- Julia Kubanek, Ph.D., professor and associate dean, School of Biological Sciences, College of Sciences

- Thomas E. Noonan, chairman, TEN Holdings LLC

- Harold R. Reynolds, CEO, BankSouth

- Beril Toktay, Ph.D., professor of operations management, Scheller College of Business

Desai

$25 Million Award Will Support Nuclear Nonproliferation R&D, Education

Woodruff Alumna Wei Chen Elected to NAE

Woodruff School graduate Wei Chen is has been elected to the National Academy of Engineering (NAE). Chen, who graduated from Georgia Tech with a Ph.D in mechanical engineering in 1995, is the Wilson-Cook Professor in Engineering Design and Professor of Mechanical Engineering at Northwestern University's McCormick School of Engineering. She was honored for"contributions to design under uncertainty in products and systems, and leadership in the engineering design community."

Woodruff School graduate Wei Chen is has been elected to the National Academy of Engineering (NAE). Chen, who graduated from Georgia Tech with a Ph.D in mechanical engineering in 1995, is the Wilson-Cook Professor in Engineering Design and Professor of Mechanical Engineering at Northwestern University's McCormick School of Engineering. She was honored for"contributions to design under uncertainty in products and systems, and leadership in the engineering design community."

Chen was one of 86 new members and 18 new foreign members announced by the NAE on February 7. She will not be the only 2019 inductee with Georgia Tech ties when the induction ceremony takes place on October 6 in Washington, D.C. Joining her will be Georgia Tech aerospace professor Krishan K. Ahuja and John H. Koon, professor of the practice Georgia Tech's School of Civil and Envionmental Engineering.

NAE members with connections to the Woodruff School include professor Jan Shi, adjunct professor Tim Lieuwen, and professors emeritus Bob Nerem, Ward Winer and Ben Zinn.

Founded in 1964, the National Academy of Engineering is a private, independent, nonprofit institution that provides engineering leadership in service to the nation. It has more than 2,000 peer-elected members and foreign associates, senior professionals in business, academia and government, who are among the world’s most accomplished engineers.

Dingreville

PatcherBot Going to Market

Automation technology developed in lab of Georgia Tech researcher Craig Forest being commercialized

For decades, a laboratory technique called patch clamping has been the gold standard for measuring the electrical properties of individual cells.

“Thousands of people practice this technique every day around the world,” says Craig Forest, a researcher in the Petit Institute for Bioengineering and Bioscience at Georgia Tech. “But it is painfully tedious and time consuming.”

“Thousands of people practice this technique every day around the world,” says Craig Forest, a researcher in the Petit Institute for Bioengineering and Bioscience at Georgia Tech. “But it is painfully tedious and time consuming.”McDowell Awarded Sloan Fellowship

Trailblazer Lecture Series

Interested students, faculty, staff, alumni, and members of the community are invited to join the George W. Woodruff School of Mechanical Engineering for the first two installments of the Trailblazer Lecture Series which will bring influential leaders in engineering to the Georgia Tech campus to share their experiences.

Interested students, faculty, staff, alumni, and members of the community are invited to join the George W. Woodruff School of Mechanical Engineering for the first two installments of the Trailblazer Lecture Series which will bring influential leaders in engineering to the Georgia Tech campus to share their experiences. Fu and Hatzell Each Win NSF CAREER Awards

"The Woodruff School congratulates Professors Kate Fu and Marta Hatzell on their NSF CAREER Awards," said Dr. Samuel Graham, Chair of the Woodruff School of Mechanical Engineering at Georgia Tech. "These awards are a result of the leadership they have demonstrated in their fields and their vision to address critical challenges that must be solved in order to move these fields to the next level. We are excited about these opportunities for Professors Fu and Hatzell and the inspiration and training they will bring to the next generation of researchers."

Graduate Program Rankings Announced

The U.S. News & World Report engineering graduate programs were released on March 12, 2019, with the George W. Woodruff School's mechanical engineering program ranking fifth and nuclear engineering placing ninth in their fields.

2019 Rankings for Georgia Tech's Engineering Graduate Programs

Satish Kumar Named ASME Fellow

Satish Kumar has been elected a Fellow of the American Society of Mechanical Engineers (ASME). The ASME Committee of Past Presidents confers the Fellow grade of membership on worthy candidates to recognize their outstanding engineering achievements. This distinction has been bestowed upon only 2% of ASME’s 130,000 members.

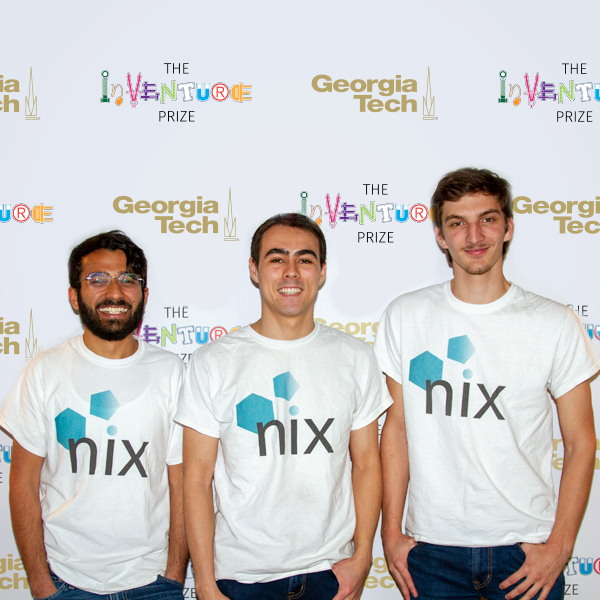

Satish Kumar has been elected a Fellow of the American Society of Mechanical Engineers (ASME). The ASME Committee of Past Presidents confers the Fellow grade of membership on worthy candidates to recognize their outstanding engineering achievements. This distinction has been bestowed upon only 2% of ASME’s 130,000 members. InVenture Prize Winners Include ME Students

Managing the Magic

It’s no secret that many Georgia Tech engineers move into leadership roles as their careers progress. Leadership just seems to be in the DNA of many of our graduates. But what makes an exceptional leader and how exactly do our alumni rise to these positions?

It’s no secret that many Georgia Tech engineers move into leadership roles as their careers progress. Leadership just seems to be in the DNA of many of our graduates. But what makes an exceptional leader and how exactly do our alumni rise to these positions?

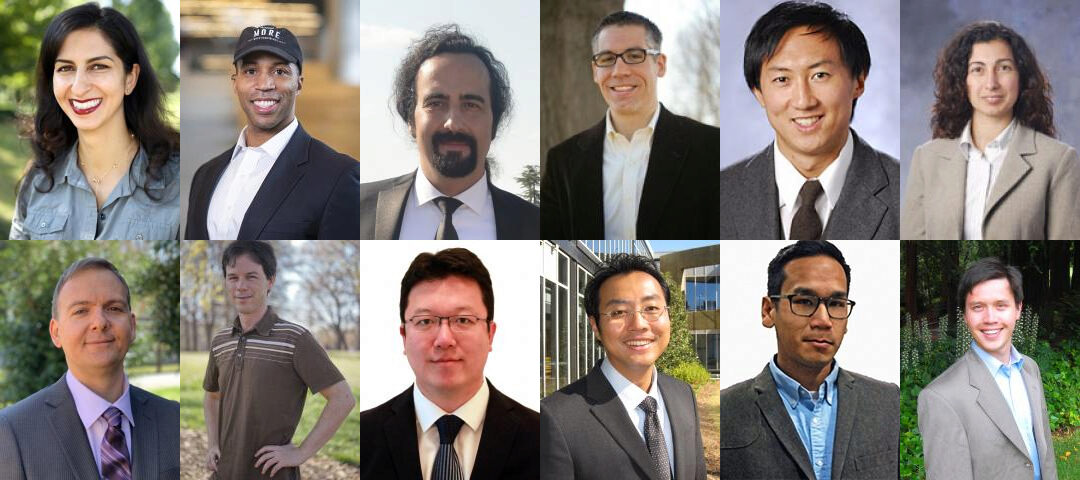

Twelve Faculty Members Awarded Promotion

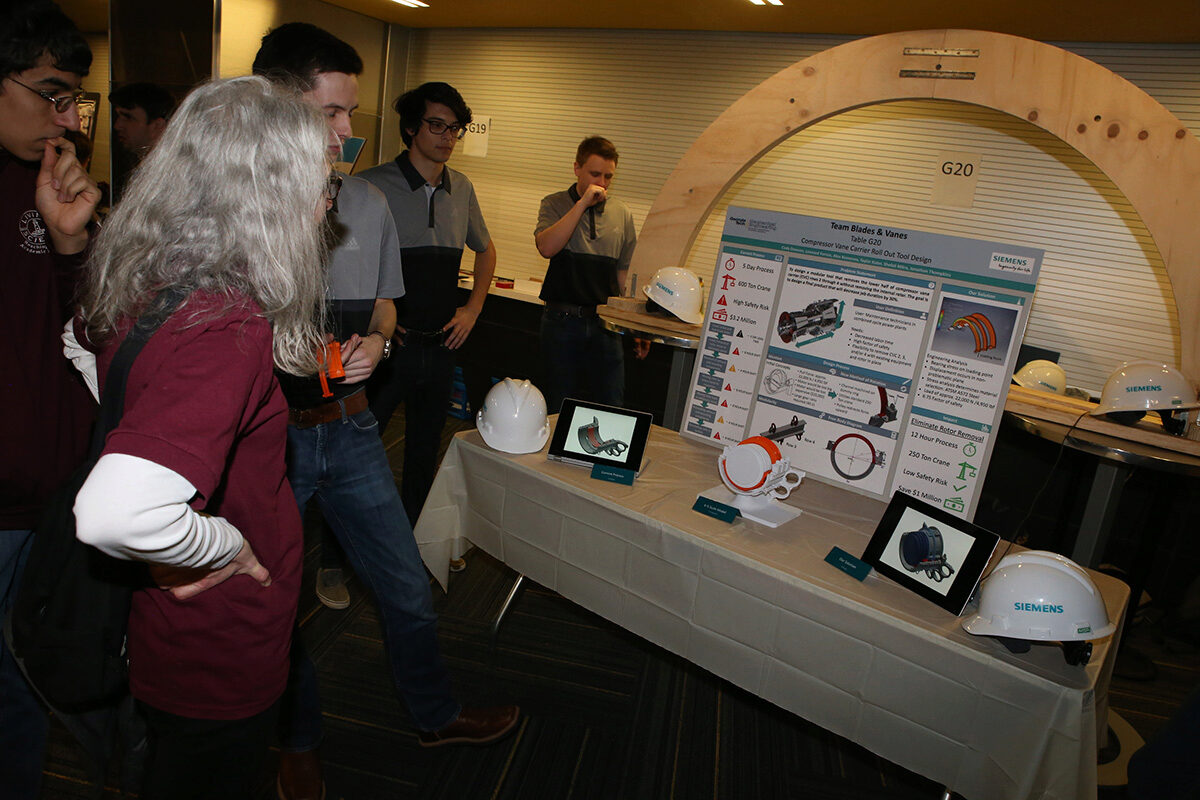

Capstone Design Past Sponsor Spotlight: Siemens

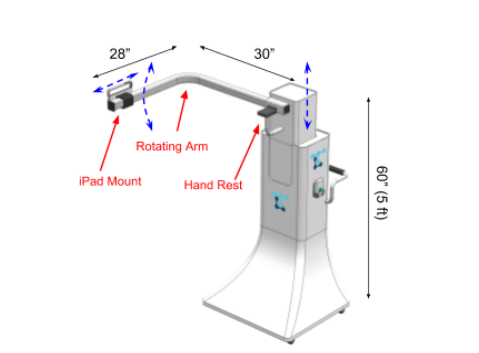

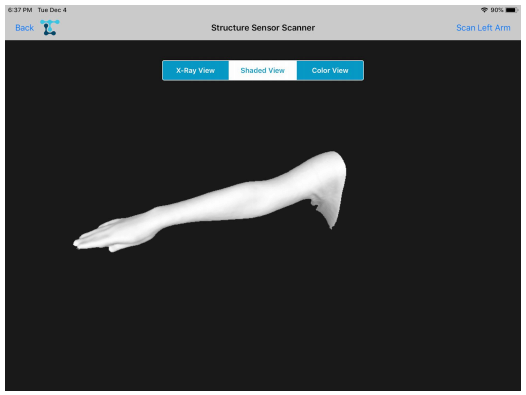

Capstone Sponsor Spotlight: LymphaTech

Capstone season is upon us and there are over 50 Mechanical Engineering teams showcasing their projects at the Expo on April 23rd at the McCamish Pavilion. The Capstone Design course is generously supported by numerous corporate partners and alumni. This weekly article series will highlight a few select sponsors, their projects, and the student teams working on their projects.

Ritchie

Woodruff Graduates Hoonred at CoE Alumni Awards

Academy of Distinguished Engineering Alumni

Q. William Hammack School of Business at Oglethorpe University

Engineering Hall of Fame

Doctoral Student Earns Vertical Flight Society Scholarship