By merging the ancient art of origami with 21st century technology, researchers have created a one-step approach to fabricating complex origami structures whose light weight, expandability, and strength could have applications in everything from biomedical devices to equipment used in space exploration. Until now, making such structures has involved multiple steps, more than one material, and assembly from smaller parts.

By merging the ancient art of origami with 21st century technology, researchers have created a one-step approach to fabricating complex origami structures whose light weight, expandability, and strength could have applications in everything from biomedical devices to equipment used in space exploration. Until now, making such structures has involved multiple steps, more than one material, and assembly from smaller parts.

“What we have here is the proof of concept of an integrated system for manufacturing complex origami. It has tremendous potential applications,” said Glaucio H. Paulino, the Raymond Allen Jones Chair and professor at the School of Civil and Environmental Engineering at the Georgia Institute of Technology and a leader in the growing field of origami engineering, or using the principles of origami, mathematics and geometry to make useful things. Last fall Georgia Tech became the first university in the country to offer a course on origami engineering, which Paulino taught.

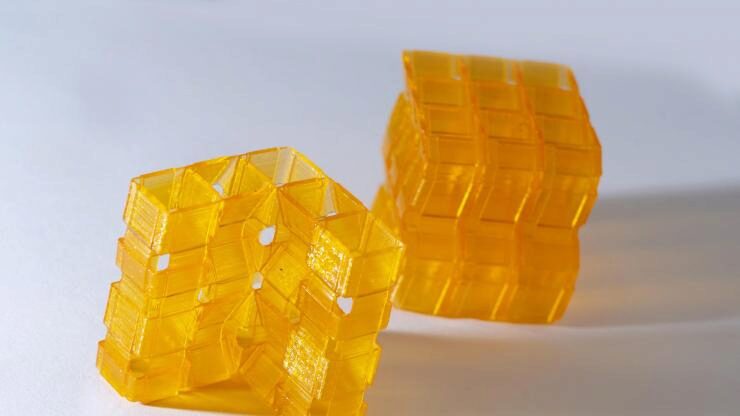

The researchers used a relatively new kind of 3D printing called Digital Light Processing (DLP) to create groundbreaking origami structures that are not only capable of holding significant weight but can also be folded and refolded repeatedly in an action similar to the slow push and pull of an accordion. When Paulino first reported these structures, or “zippered tubes,” in 2015, they were made of paper and required gluing. In the current work, the zippered tubes – and complex structures made out of them – are composed of one plastic (a polymer) and do not require assembly.

The work was reported in a recent issue of Soft Matter, a journal published by the Royal Society of Chemistry. The primary authors are Paulino; H. Jerry Qi, The Woodruff Faculty Fellow in Georgia Tech’s George W. Woodruff School of Mechanical Engineering; and Daining Fang of Peking University and the Beijing Institute of Technology. Other authors are Zeang Zhao, a visiting student at Georgia Tech now at Peking University; Qiang Zhang of Peking University; and Xiao Kuang and Jiangtao Wu of Georgia Tech.

An Emerging Technology

There are many different types of 3D printing technologies. The most familiar, inkjet, has been around for some 20 years. But until now, it has been difficult to create 3D-printed structures with the intricate hollow features associated with complex origami because removing the supporting materials necessary to print these structures is challenging. Further, unlike paper, the 3D-printed materials could not be folded numerous times without breaking.

Enter DLP and some creative engineering. According to Qi, a leader in the emerging field collaborating with Fang’s group at Peking University, DLP has been in the lab for a while, but commercialization only began about five years ago. Unlike other 3D printing techniques, it creates structures by printing successive layers of a liquid resin that is then cured, or hardened, by ultraviolet light.

For the current work, the researchers first developed a new resin that, when cured, is very strong. “We wanted a material that is not only soft, but can also be folded hundreds of times without breaking,” said Qi. The resin, in turn, is key to an equally important element of the work: tiny hinges. These hinges, which occur along the creases where the origami structure folds, allow folding because they are made of a thinner layer of resin than the larger panels of which they are part. (The panels make up the bulk of the structure.)

Together the new resin and hinges worked. The team used DLP to create several origami structures ranging from the individual origami cells that the zippered tubes are composed of to a complex bridge composed of many zippered tubes. All were subjected to tests that showed they were not only capable of carrying about 100 times the weight of the origami structure, but also could be repeatedly folded and unfolded without breaking. “I have a piece that I printed about six months ago that I demonstrate for people all the time, and it’s still fine,” said Qi.

What’s Next?

What’s next? Among other things, Qi is working to make the printing even easier while also exploring ways to print materials with different properties. Meanwhile, Paulino’s team recently created a new origami pattern on the computer that he is excited about but that he has been unable to physically make because it is so complex. “I think the new system could bring it to life,” he said.

The principal funders of the work were the Air Force Office of Scientific Research (FA9550-16-1-0169), the National Science Foundation (CMMI-1462894, CMMI-1462895, and CMMI-1538830), the Raymond Allen Jones Chair at Georgia Tech, the National Natural Science Foundation of China, and the National Materials Genome Project of China.

CITATION: Zeang Zhao, et al., “3D printing of complex origami assemblages for reconfigurable structures,” (Soft Matter 39, 2018) http://dx.doi.org/10.1039/c8sm01341a

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181 USA

Media Relations Contact: John Toon (404-894-6986) (jtoon@gatech.edu).

Writer: Elizabeth Thomson

Origami, 3D Printing Merge to Make Complex Structures in One Shot

New Material, Manufacturing Use Sun's Heat for Cheaper Renewable Electricity

Solar power accounts for less than two percent of U.S. electricity, but could make up more than that if the cost of electricity generation and energy storage for use on cloudy days and at nighttime were cheaper.

Solar power accounts for less than two percent of U.S. electricity, but could make up more than that if the cost of electricity generation and energy storage for use on cloudy days and at nighttime were cheaper.

A Purdue University-led team that included researchers from Georgia Tech have developed a new material and manufacturing process that would make one way to use solar power – as heat energy – more efficient in generating electricity.

The innovation is an important step for putting solar heat-to-electricity generation in direct cost competition with fossil fuels, which generate more than 60 percent of electricity in the U.S.

“Storing solar energy as heat can already be cheaper than storing energy via batteries, so the next step is reducing the cost of generating electricity from the sun's heat with the added benefit of zero greenhouse gas emissions,” said Kenneth Sandhage, Purdue’s Reilly Professor of Materials Engineering.

The research, which was done at Purdue in collaboration with the Georgia Institute of Technology, the University of Wisconsin-Madison and Oak Ridge National Laboratory, published in the journal Nature on October 18.

Solar power doesn't only generate electricity via panels in farms or on rooftops. Another option is concentrated power plants that run on heat energy.

Concentrated solar power plants convert solar energy into electricity by using mirrors or lenses to concentrate a lot of light onto a small area, which generates heat that is transferred to a molten salt. Heat from the molten salt is then transferred to a "working" fluid, supercritical carbon dioxide, that expands and works to spin a turbine for generating electricity.

To make solar-powered electricity cheaper, the turbine engine would need to generate even more electricity for the same amount of heat, which means the engine needs to run hotter.

The problem is that heat exchangers, which transfer heat from the hot molten salt to the working fluid, are currently made of stainless steel or nickel-based alloys that get too soft at the desired higher temperatures and at the elevated pressure of supercritical carbon dioxide.

Inspired by the materials his group had previously combined to make composite materials that can handle high heat and pressure for applications like solid-fuel rocket nozzles, Sandhage worked with Asegun Henry – formerly at Georgia Tech, but now at the Massachusetts Institute of Technology – to conceive of a similar composite for more robust heat exchangers.

Two materials showed promise together as a composite: The ceramic zirconium carbide, and the metal tungsten.

Purdue researchers created plates of the ceramic-metal composite. The plates host customizable channels for tailoring the exchange of heat, based on simulations of the channels conducted at Georgia Tech by Devesh Ranjan's team.

“We simulated the printed circuit heat exchanger, which contains channels that are straight and parallel with semi-circular cross sections two millimeters in diameter,” said Ranjan, associate professor in the George W. Woodruff School of Mechanical Engineering. “The thickness of each plate in the printed circuit heat exchanger stack and the spacing between the channels were then determined from the maximum allowed stresses for each type of material, with a factor of safety added.”

Mechanical tests by Edgar Lara-Curzio’s team at Oak Ridge National Laboratory and corrosion tests by Mark Anderson’s team at Wisconsin-Madison helped show that this new composite material could be tailored to successfully withstand the higher temperature, high-pressure supercritical carbon dioxide needed for generating electricity more efficiently than today’s heat exchangers.

An economic analysis by Georgia Tech and Purdue researchers also showed that the scaled-up manufacturing of these heat exchangers could be conducted at comparable or lower cost than for stainless steel or nickel alloy-based ones.

“Ultimately, with continued development, this technology would allow for large-scale penetration of renewable solar energy into the electricity grid,” Sandhage said. “This would mean dramatic reductions in man-made carbon dioxide emissions from electricity production.”

A patent application has been filed for this advancement. The work is supported by the U.S. Department of Energy, which has also recently awarded additional funding for further development and scaling up the technology.

This story was provided by Purdue University.

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181

Media Relations Contacts: Purdue (Kayla Wiles, 765-494-2432, wiles5@purdue.edu); Georgia Tech (John Toon, 404-894-6986, (jtoon@gatech.edu)

Writer: Kayla Wiles, Purdue University

Order Form

Sonnen Inc. Sponsors Capstone Team

Capstone season is upon us and there are over 50 Mechanical Engineering teams showcasing their projects at the Expo on December 4th at the McCamish Pavilion! The Capstone Design course is generously supported by numerous corporate partners and alumni. This week’s spotlight sponsor is first-time Capstone Design sponsor, Sonnen. Sonnen is an energy storage company headquartered in Germany that designs and manufactures batteries for residential and small business use. Sonnen’s vision is for “everyone… to cover their energy needs with [a] decentralized and clean energy source”. The company sticks to its principles of clean energy as their headquarters is in Wildpoldsried, which is a village that is currently running on 100% clean and renewable energy. By producing the sonnenBatterie, the company has already begun making energy storage systems available to the mass market.

Team 1: EnerJackets - Alex Gray, Rafael Garcia, Keivan Farhan, Kenta Yasuda, Madeline Kanne, Kate Moss

Problem: Sonnen’s energy storage systems use Lithium-ion batteries that must stay between -10 to 45 degrees Celsius to function properly. The largest Sonnen energy storage system designed for the mass market is approximately the size of a refrigerator. Currently, Sonnen’s battery storage systems can only be used indoors where temperature can be regulated. Because of the inverter’s size, they are limited to consumers that can manage the large indoor space consumption.

Projected Impact: By creating a casing for the batteries that can withstand outside elements and temperatures, Sonnen can market their product to places in more extreme climates and a larger portion of their target market. A weather-proof and temperature regulated casing removes the indoor space constraint. This allows consumers to install the energy storage outdoors, similarly to an air conditioning unit making it more convenient for residential consumers. Sonnen has a European community called sonnenCommunity where consumers can produce and store their own power while sharing their additional energy with other members of the community. This is the beginning of achieving their vision of clean energy becoming commonplace within the next 20-30 years.

Proposed Solution: Team ‘EnerJackets’ is creating a battery enclosure to protect Sonnen batteries from outside elements. The solution that the team creates must have an IP 54 rating, meaning that it must protect the battery from solid particles larger than 1 mm and be protected from water 60 degrees off of the vertical. The battery must also be able to function with outdoor temperatures of 0 to 115 degrees Fahrenheit. They must be able to remove 143 watts of heat for their design to be successful. So far, the team has been experimenting with different fan models and the number of fans used to cool the enclosure. They are running computational fluid dynamics (CFD) on SolidWorks to test various scenarios and determine the best most effective option.

Team 2: The Jigawatts sonnen Project 2: Electric Boogaloo - Jeremy Leff, Eugene Lee, Chris Nowack, Kristie Teoh, Kyle Olson, Lorenzo Garcia

Problem: According to a research paper written by Dr. Salahuddin Qazi and Mr. Farhan Qazi called “Green Technology for Disaster Relief and Remote Areas”, the number of natural disasters worldwide has increased steadily over the past 40 years. After a natural disaster, the infrastructure for that area is damaged or destroyed. This can leave disaster-hit areas without access to electricity for days or even years. Power generators are typically brought in by disaster relief authorities, but they are often large and bulky which can make them difficult to move to disaster areas.

Projected Impact: When Hurricane Maria hit Puerto Rico in 2017, at least 11% of homes and businesses on the island did not have electricity restored within 6 months. When the storm hit, 80% of the island’s power lines and generators were rendered unusable leading to the longest and largest blackout in US history. After the disaster, large solar panels were shipped in and set up in affected areas to provide power off the grid. The goal for this project is to create a portable solar-powered generator that can be moved by a single person. With disaster zones, large solar panel farms may not be feasible for all affected areas. The option of a small, mobile device may help families who do not have access to power set up by disaster-relief efforts.

Proposed Solution: Sonnen is enlisting help from a team of Georgia tech students to create a small and portable solar-powered generator using an existing sonnen battery. Their main focus will be on the portability aspect of the generator. The team has designed their solution using CAD software and plan to build out a prototype using wood and metal for proof of concept. Their design include a retractable handle for users to grab onto when transporting the generator but that also tuskc away to make it more compact. They plan to build a full-scale prototype later-on using aluminum because the metal is cheap and lightweight.

Check out these projects and over 200 other exciting capstone design teams at the Fall 2018 Capstone Design Expo on December 4th at 3 pm in the McCamish Pavilion. More information on how to RSVP is on the website here: http://expo.gatech.edu/. Please invite friends and family to attend and cheer for our graduating seniors!

All senior students in Mechanical Engineering culminate their undergraduate educational experience with the Senior Capstone Design course in order to provide firsthand experience at solving real world problems in a team environment. Students typically work in teams of four to six individuals and each team is advised by a faculty member. Companies interested in submitting a project for consideration can contact Dr. Amit S. Jariwala, at 404-894-3931 or via email at: amit.jariwala@gatech.edu.

Members of Woodruff School Community Recognized at ASME IMECE Meeting

Five individuals with ties to the Woodruff School were recognized at the ASME International Mechanical Engineering Congress & Exposition on November 15 in Pittsburgh, PA. These individuals include Bob Nerem, Tim Lieuwen, Todd Allen, Sean Wu, and Asegun Henry.

Bob Nerem, Professor Emeritus - ASME Honorary Membership

Honorary Membership has come to be regarded as recognition of a lifetime of service to engineering or related fields. Dr. Nerem was honored for outstanding contributions to the understanding of the dynamics of blood flow in health and disease and the development of tissue engineering and regenerative medicine. In addition, Dr. Nerem has provided seminal leadership in creating opportunities for engineers to play a vital role in advancing medicine.

Tim Lieuwen, Professor - George Westinghouse Medal

The George Westinghouse Medal was established to recognize eminent achievement or distinguished service in the power field of mechanical engineering.

Todd Allen (BSME 83) - Henry Laurence Gantt Medal

The Henry Laurence Gantt Medal recognizes distinguished achievement in management and for service to the community. Dr. Allen is also a "Board-elect" and will begin service on the ASME Board of Governors in June 2019.

Sean Wu (PhD Alumnus and Professor at Wayne State University) - Per Bruel Medal

The Per Bruel Gold Medal for Noise Control and Acoustics is given in recognition of eminent achievement and extraordinary merit in the field of noise control and acoustics.

Asegun Henry (former Woodruff School faculty member) - Bergles-Rohsenow Young Investigator Award in Heat Transfer

Wright

Erisman

Solving a 75-Year-Old Mystery Might Provide a New Source of Farm Fertilizer

The solution to a 75-year-old materials mystery might one day allow farmers in developing nations to produce their own fertilizer on demand, using sunlight and nitrogen from the air.

The solution to a 75-year-old materials mystery might one day allow farmers in developing nations to produce their own fertilizer on demand, using sunlight and nitrogen from the air.Kawneer Sponsors Capstone Team

Capstone Season is upon us and there are over 50 Mechanical Engineering teams showcasing their projects at the Expo on December 4th at the McCamish Pavilion! The Capstone Design course is generously supported by numerous corporate partners and alumni. This weekly article series will highlight a few select sponsors, their projects and the student teams working on their projects.

This week’s spotlight sponsor is first-time Capstone Design sponsor, Kawneer, an Arconic Company. They focus on providing products for the commercial construction industry, and Kawneer is the leading manufacturer of architectural products and systems in North America. They are known for their blast mitigating products, high-thermal performance products, and hurricane resistant sliding glass doors. Kawneer allowed the student teams to visit a research and development location in Georgia where the teams learned about Kawneer’s door designs and how the company tests their glass doors for leaks. There, the teams were able to learn more about the processes that Kawneer uses for testing.

Problem: Sliding glass doors near hurricane-prone areas are difficult for people who do not have their full range of motion. The weathering strips on Kawneer’s hurricane-proof sliding glass door frames require 7 pounds of force to move the glass doors one inch off of the weathering strips. The glass doors themselves require 5 pounds of force to slide open once it has be disengaged from the weathering strips. The teams need to create a solution that is ADA compliant and will allow people to easily open and close hurricane-proof, sliding glass doors.

Projected Impact: According to Team Door Jamz’s research, 19.9 million people struggle with lifting and grasping objects in the United States. Kawneer’s target market for the new door-opening mechanism is people in the US who are over the age of 65. That population has higher rates of arthritis, carpal tunnel syndrome, and other illnesses that reduce motor function. According to the Population Reference Bureau, approximately 18% of the people living in Florida are over the age of 65. Many older citizens have a reduced range of motion or are unable to grasp objects as well as when they were younger. Due to its warm weather and plentiful beaches Florida is a popular location for installing Kawneer’s weather-proof, sliding glass doors. If the amount of force required to open glassdoors is reduced, it increases the independence for people who have issues grasping objects or a limited range of motion.

Team 1: Team Mavericks– Jacob Thomas, Thomas Cheng, Pranav Chunduri, Jason Paulose, Gonzalo Barreto, Saikamal Srinivas

Proposed Solution: Team ‘Mavericks’ is creating a handle that will multiply a user’s force 2.4 times. Users will only need to be able to use 5 pounds of force to disengage the door from the weathering strips on the door frame. They have designed a handle that revolves to push out a 12 pound block disengaging the door. One of their challenges so far has been fitting the door-opening components into a door frame. The components must be small enough to be hidden within a door frame as well as durable. The team will be 3D-printing out their mechanism using ultra high molecular weight polyethylene (UHMW-PE), a low-friction plastic. They have tested out the durability of their concept using SolidWorks, letting them look at how the mechanism will wear after repeated cycling.

Team 2: Team Door Jamz– John Mitchell, Scott Bowden, David Johnston, Andrew Agliata, Katherine Freesemann, Clare Specht

Proposed Solution: Team ‘Door Jamz’ is using a specialized glove, borrowed from Dr. Brad Fain, which mimics arthritis to develop their solution. Using their experience with the glove the team will design and test a door-opening mechanism to reduce the amount of force required to open the door by 50% while retaining the structural soundness of Kawneer’s doors. The team will be designing a user interface for a door frame and door that Kawneer already produces. So far, the team has 3D-printed a prototype for their door handle.

Check out these projects and over 200 other exciting capstone design teams at the Fall 2018 Capstone Design Expo on December 4th at 3 pm in the McCamish Pavilion. More information on how to RSVP is on the website here: http://expo.gatech.edu/. Please invite friends and family to attend and cheer for our graduating seniors!

All senior students in Mechanical Engineering culminate their undergraduate educational experience with the Senior Capstone Design course in order to provide firsthand experience at solving real world problems in a team environment. Students typically work in teams of four to six individuals and each team is advised by a faculty member. Companies interested in submitting a project for consideration can contact Dr. Amit S. Jariwala, at 404-894-3931 or via email at: amit.jariwala@gatech.edu.

test

2018 Fall Capstone Expo Results

As doctors get better at treating diseases, engineers continue to discover new solutions to medical issues that were previously thought to be impossible to solve. College of Engineering seniors were no different at this year’s Capstone Design Expo, with many of the teams concentrating their efforts on preventing, diagnosing, and treating diseases and health concerns.

![]() Overall winner: Supleurative

Overall winner: Supleurative

Hannah Choi, Atlanta, Georgia

Tara Ramachandran, Scarsdale, New York

Aerospace Engineering: The Squirrel Works

Biomedical Engineering: aMAYOnnaising

Civil and Environmental Engineering: BAMM Engineering

Electrical and Computer Engineering: PulseScan

Industrial Design and Mechanical Engineering: Chopa

Industrial and Systems Engineering: Cox Automotive

Mechanical Engineering (tie): W(hole) lotta trouble

![Team Send It! with Buzz Team Send It! with Buzz]() Mechanical Engineering (tie): Send It!

Mechanical Engineering (tie): Send It!

Interdisciplinary: PPEeps

For more photos from Capstone, visit our Flickr gallery.

Story by Polly Ouellette, College of Engineering Dean's Office.

Mazumdar

Volleyball Player, NRE Major Coral Kazaroff Featured by GT Athletics

#TGW: THE ROAD NOT TAKEN

Brian Schumacher - 12/31/2018 06:03:40 pm

Powerful X-ray Beams Unlock Secrets of Nanoscale Crystal Formation

Hailong Chen and graduate research assistant Xuetian Ma

Read the rest of the story at Georgia Tech Research Horizons.

Jon Rogers Appears on Dean McLaughlin's Podcast

George W. Woodruff School of Mechanical Engineering assistant professor Jon Rogers was invited to appear on Dean Steve McLaughlin's podcast, The Uncommon Engineer, to discuss his research with drones. Listen as he talks about their applications in agriculture, rescue missions, and much more, as well as the challenges drones present when it comes to privacy, personal protection, and surveillance.

Yee Receives Office of Naval Research Young Investigator Award

Assistant professor Shannon Yee has received an Office of Naval Research Young Investigator Award for his research project entitled “Switchable Organic Thermal Elements.”

Ranjan Named Associate Chair for Research

Associate Professor Dr. Devesh Ranjan has accepted the position of Associate Chair for Research in the George W. Woodruff School of Mechanical Engineering (effective January 1).

Associate Professor Dr. Devesh Ranjan has accepted the position of Associate Chair for Research in the George W. Woodruff School of Mechanical Engineering (effective January 1).

The Associate Chair for Research is responsible for working with the Woodruff School’s faculty to develop a strategic research plan for future growth and investments in the school. In addition, Dr. Ranjan will help to identify new research opportunities, help to foster strategic relationships with government, industry, and foundations, and help to synergize research efforts with other units in the College of Engineering and across the Institute. The Associate Chair for Research will also serve as a focal point to help improve the research support for faculty within the Woodruff School, which will include interactions with OSP as well as space and facility resources.

"I am excited to have the opportunity to work with Devesh to address the research needs of the Woodruff School and look forward to seeing the growth that he will help foster in our program," said Dr. Samuel Graham, Chair of the George W. Woodruff School of Mechanical Engineering.

Volunteer Work Earns First-year Student Philanthropy Award

A passion for helping others led to first-year mechanical engineering student Brooke Waller being awarded the 2018 Outstanding Youth in Philanthropy Award from the St. Louis Chapter of the Association of Fundraising Professionals. In this Q&A she talks about her volunteer work, why she chose Georgia Tech, what drew her to mechanical engineering, and what she loves about being here.

Where are you from and where did you grow up?

Where are you from and where did you grow up?

I'm from St. Louis, Missouri. I was born in a small town in Illinois, but I've lived in Missouri most of my life. I have identical twin brother who just turned 15. It's a lot of fun. I like to watch their soccer and basketball games.

What were you involved in while you were in high school?

In high school I worked in a local restaurant, called Sugo's. It's an Italian place. It was pretty much my favorite thing I ever did. I got really close to everyone who worked there. I played basketball for a little while in high school, but then our team kind of fell apart and that's how I wound up at the restaurant. I also went to church and volunteered. That's how I filled my time.

How did you get involved in volunteer work?

I got into a charity called Eye Care Charity of Mid-America. My dad was on the board, and they had a grant to fulfill for Hispanic children. A lot of them don't speak English, and they're in kindergarten, first grade, second grade, or sometimes older. They have two buses that serve as mobile eye clinics, so they brought me on to the bus and I acted as a translator for the kids and the doctors. I just tried to make them feel more at home. It's a strange environment for them to be in, so I tried to make it a little less scary. The buses have two exam lanes on them, with two doctors. The kids come in and they see a doctor, and they get their lenses cut the same day and they walk off the bus with a new pair of glasses. It's a big help to at risk youth. If they can't see the board they aren't going to be able to do well in school. It helps them break the cycle and find success in school. I worked with them for two years.

Then during my senior year in high school I was the executive director for Ladue Dance Marathon. Dance Marathon benefits the Children's Miracle Network of Greater St. Louis which includes St. Louis Children's Hospital and SSM Health Cardinal Glennon Children's Hospital. We provide funding for the extra stuff insurance doesn't cover to make their stay a little bit better, like clown doctors, a library, tutoring services so kids can keep up with their school work as they're in and out of hospital, and that sort of thing. We had 22 members on our board and then I had a co-executive director. My junior year I participated just as a dancer and we raised $44,000. We set our goal last year for $50,000 and we ended up raising $81,000. It was a fun, but very busy year. It was totally student run aside from two faculty advisors who were there to sign paperwork and that sort of thing. It was a group effort and it was very rewarding. Our school had about 1200 students, and the exec board was made up mostly of upperclassmen, then there was a subcommittee called morale that makes up a dance and keeps people pumped up. Our event was 6 hours, all on our feet to honor the nurses who do that every day.

How did you become fluent in Spanish?

Working in the restaurant is what made me fluent in Spanish. A lot of my friends from work are from Honduras and Mexico, and I was working there four days a week, so I took Spanish in high school but learned exponentially more in the restaurant. I started in the restaurant and volunteering at the same time, but working there helped my Spanish so much. I'm so thankful for that experience.

Describe what it was like to win an award for your charity work. Were you surprised?

The Association of Fundraising Professionals for St. Louis gave out the award. My youth pastor from my church actually nominated me. I didn't even know about it until my mom told me- I was so surprised. My pastor had to get recommendation letters from Eye Care Charity of Mid-America and Dance Marathon for it. Oddly enough, I found out when I was in Atlanta in April for Georgia Tech admitted students day, so that's kind of funny. I could only accept it if I was able to go home to accept it. I was able to do it, and accepting the award for Outstanding Youth in Philanthropy in November. The rest of the recipients at the ceremony were adults, so it was a little bit intimidating. It was very nice though. My sponsors made a nice video, and that was fun.

Has your volunteer work continued at Georgia Tech?

I've gotten involved with the Tech Dance Marathon as well, which is done by For the Kids. I'm the manager of strategic partnerships for them, which involves reaching out to corporations to partner on various projects. That's been fun. I'm also involved in Greek life, and I plan to get involved in some of the motor sports clubs on campus. I'm still exploring my options, but it's something I really want to do. My linear algebra TA is involved with GT Motorsports and he's been giving me advice on where I could fit in. My first semester was a whirlwind so I haven't figured it all out yet.

Why did you choose Georgia Tech?

As a mechanical engineering major, choosing Tech wasn't hard. I always wanted to go to a school in the South. I looked at northern schools, but I don't like the cold and I think my personality fits the South better. Basically, I wanted a top engineering school, in a big city, in the South. Georgia Tech offered all of those- a top ranked school in Atlanta with all of its resources, in the South. I'm so happy here. This is my place. I started in the summer and I love everything about it. It's definitely a challenge, but that's what I signed up for. That's why I'm here.

What are you favorite things about being a Georgia Tech student?

I love going to football games. That's one of my favorite social things. But I think it's just been a great fit for my personality. Everyone here is so driven to do amazing things. People take school seriously, and that's how I wanted to live my life. My professors have been amazing- I love all them so far. I'm really enjoying the fact that Tech is everything I thought it would be.

What was the biggest surprise about Tech during your first semester?

I was expecting it to be challenging, but it was still harder than I thought. I wanted that though. Now I know how to prepare for this semester and I know what professors expect. Being on your own the first time is a challenge for anyone.

What drew you to mechanical engineering?

I really want to do aerospace and automobile parts manufacturing. Mechanical engineering is a general degree, which gives me the opportunity to move around and try different things. I want to end up in automotive manufacturing or aerospace though, and I know this gives me the tools for both.

Do you plan to do the co-op program or study abroad?

I'm actually studying abroad this summer through the Oxford program. I've been abroad to Japan, but never to Europe. I'm really looking forward to traveling and taking pictures. And eventually I'm sure I'll co-op, ideally in the automotive industry.

Do you think you’ll find a way to combine your academic interests with philanthropy?

I'd love to combine philanthropy with my academic interests, but I'm not sure what that looks like yet. I'll be involved in philanthropy for the rest of my life in one way or another. It's so rewarding and has opened so many doors for me.

I want to set myself up for a productive future, and just figure out where I fit. I know that sounds broad, but I want to keep an open mind while I figure out how I can make an impact.

Overall winner: Supleurative

Overall winner: Supleurative Mechanical Engineering (tie): Send It!

Mechanical Engineering (tie): Send It!