![Robert Guldberg, Executive Director, Parker H. Petit Institute for Bioengineering and Bioscience and Mechanical Engineering Professor Robert Guldberg, Executive Director, Parker H. Petit Institute for Bioengineering and Bioscience and Mechanical Engineering Professor]()

Tennis elbow, a pulled hamstring, shin splints or an ankle sprain. We’ve all dealt with common sports injuries in an attempt to get in shape. Faculty at Georgia Tech’s College of Engineering are laser focused on providing sports medicine for even the most common injury. Past that, extracellular matrix therapies, regenerative medicine and wearable joint sensory technology are just a few of their more advanced focus areas. Sports medicine today has become a specialized field with many facets. No longer just a study of orthopedics, sports medicine now encompasses new therapies and technologies that tackle all sorts of sports-related injuries and diseases, leveraging predictive analytics and wearables to keep athletes performing at their best.

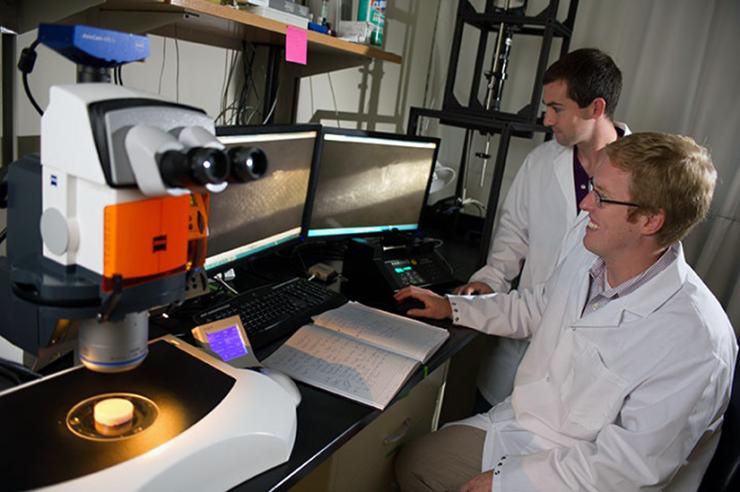

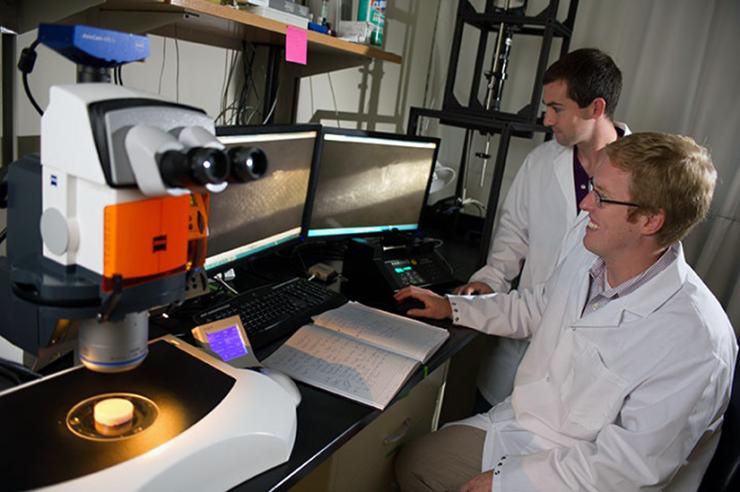

Tech’s sports medicine research program continues to grow, led by faculty such as Robert Guldberg, Omer Inan, Michelle LaPlaca and Johnna Temenoff, all leaders at the top of the field. Each of these engineers has made impactful contributions to sports medicine research, and their work is already seeing real-world application today. Each one of them is driven by a common desire to enhance the quality of life of athletes, both on and off the field. And even occasional exercisers can reap the benefits.

Baseball players today may soon reap the benefits of Robert Guldberg’s work on treatments for rotator cuff injuries, ligament tears and osteoarthritis. Guldberg has recently worked with the likes of Dr. Gary Lourie, head physician for the Atlanta Braves, whose focus is to keep athletes safe and healthy. Lourie will deliver a keynote talk on regenerative medicine at the Major League Baseball annual meeting in December. This close collaboration with Tech brings cutting edge sports medicine therapies to baseball players across the nation, keeping athletes performing at their peak.

Much of Guldberg’s research can be applied to athletes, like baseball or football players, who have early onset osteoarthritis from trauma to their bones and joints. Guldberg has recently focused on extracellular matrix (ECM) therapies for sports injuries and using stem cells to reduce inflammation and stimulate healing. As one example of an ECM therapy already in clinical use, human amniotic membrane allograft derived from placental tissue contains more than 200 prohealing proteins to make it one of the latest treatment options to help manage sports injuries.

“Injured athletes just want to get back to the playing field faster, as well as prolong their career,” said Guldberg. “In collaboration with MiMedx, Inc. in Marietta, GA, we have shown that an injectable form of micronized ECM can slow down and partially reverse post-traumatic arthritis in preclinical studies. We believe this will have a positive impact on athletes in the near future.”

Guldberg is also interested in biomaterials and bio-printing for injuries to cartilage like the meniscus. Bio-printing involves 3D printing but with living tissues. Currently, there is no real solution for a damaged meniscus. But in the future, a living meniscus could feasibly be printed. In the meantime, biomaterial hydrogels are used to replace cartilage tissue and speed recovery.

Working with biomaterials leverages Guldberg’s work in both BME and ME at Georgia Tech, and he’s interested in understanding how the mechanical environment in the body relates to the healing process. Guldberg sees a natural interface between mechanical engineering and the biosciences. His research helps answer questions such as, ‘if an athlete has a back injury, what is the optimal rehabilitation protocol for them to be up and moving again?’

In research published in the prestigious Proceedings of the National Academies of Science, Guldberg’s lab recently showed that stressing an injury site too early can disrupt revascularization and healing, while a delayed mechanical loading protocol stimulates more robust tissue repair. “We want to wait until the right moment to encourage blood vessels to grow and for tissue to start reforming, so timing is everything,” said Guldberg. ”Mechanical loading in the healing process is crucial for a speedy recovery of functional performance.”

When asked about the future of biomedical engineering, Guldberg points to predictive modeling and data analytics.

“I think the next frontier will involve working with health data analytics,” said Guldberg. “The future for healthcare is understanding all the data and using it to predict injuries and identify the optimal personalized medicine approaches to quickly return patients to full health.”

Soon, there will be predictive models for diseases like arthritis, creating the opportunity for doctors to intervene early and stop the damage. Guldberg hopes to be on the front lines of returning athletes and others to full health.

Omer Inan was a college athlete in track and field at Stanford when his passion for sports medicine began. As a discus thrower, he became interested in quantifying the health of joints to enable higher performance and influence training regimens.

Today, Inan is developing sensor-based technologies to aid the road to recovery in athletes. With pro athletes, training is occurring at a very high level, and the stress on the joints is substantial. Monitoring athletes’ bodies, particularly the joints and ligaments, can help coaches make better training decisions. Objectively-driven decisions guided by data reduce the chance of re-injury and optimize recovery.

Inan has developed a Wearable Knee Health System (WKHS) that listens to the sounds a joint makes to determine its health. The WKHS can be used during rehab to monitor swelling and structural stability improvements. It’s creating a much more objective level of monitoring. And it’s not just for knees.

“Healthy and damaged joints sound very different,” said Inan. “This wearable knee joint sensor helps evaluate joint injuries and create healing regimens. It also has preventative applications. Pitchers for example can potentially listen to their rotator cuff and decide how much pitching they should do based on the sounds.”

When Inan was throwing discus in college with his sights set on the Olympic trials, he over extended himself, cutting his career short. If his coaches had possessed technology like this, it is likely he could have competed much longer and at a higher level.

Inan’s work also takes him to Professor. Mindy Millard-Stafford’s lab at Georgia Tech, where he measures heart function in a high heat environment, like a summer ball field or football stadium. Many athletes suffer from dehydration in these conditions, and Inan is looking for a way to measure the body’s reaction based on cardiac response.

“If an athlete is performing when it’s hot, and the coach is worried about loss of fluids, we can potentially monitor changes in cardiovascular performance and decide when to rehydrate and rest,” said Inan. “We are measuring cardiovascular performance with wearable sensors, and the overall solution may be a great way to prevent heat exhaustion in athletes.”

In the future, Inan is interested in looking at overuse injuries, which he predicts to be the next big thing for joint health monitoring in sports medicine. Inan believes data analytics will help researchers study overuse injuries by quantifying injury risk with wearable sensors. Analytics are helping Inan build better sensors to gather more accurate data.

“Leveraging data and technology helps us sense and modulate,” said Inan. “It’s not just the physical hardware, but also the processing and interpretation of the data that comes from the sensors. Data analytics is a big component of our lab and helps us extract information from the data that we sense.”

Inan hopes to use analytics for overuse injury detection to help athletes avoid further damage and create a healing regimen to get them back to playing, and fast.

Michelle LaPlaca recently gave a TEDx talk on concussions, bringing her research and viewpoints to center stage for a large, engaged audience. In her talk, she makes the case for personalized health to transform the way doctors treat concussion injuries. For each athlete that suffers a concussion, LaPlaca argues you have to take into account any number of personal health factors, such as medication and preexisting conditions. Doctors can then make more objective decisions about concussion treatment and more accurately predict outcomes.

“Each of us have a brain fingerprint based on how many times you’ve hit your head in the past, what medications you’re on, your medical history, diet, etc.,” said LaPlaca during her TEDx talk. “We can take all these data points and use algorithms to create personalized finger prints that allow us to tailor diagnosis and treatment plans just for you and your brain. So this is a data-driven approach, and we can create individual plans for each athlete.”

LaPlaca advocates for personalized healthcare to diagnosis and treat concussions. She’s leveraging technology and systems thinking from her engineering background to uncover the simplest solutions to address concussion issues. LaPlaca developed DETECT (integrated Display Enhanced TEsting for Cognitive Impairment and mTBI) alongside David Wright at Emory University as a rapid concussion assessment tool for sideline evaluation of concussions. It’s an immersive tool that uses virtual reality to objectively detect deficits from several different neurological domains in just 20 minutes, taking the guesswork out of diagnosing a concussion during a game. So no more ‘how many fingers am I holding up?’

“Every concussion is different, and we are really trying to understand the complexity of the data coming out of DETECT,” said LaPlaca. “The device allows us to test balance, motor function, reaction time, neurocognitive function and oculomotor function. After you test across all these different domains, you can then make the call whether the player should go back in the game.”

LaPlaca believes the next phase for DETECT is to leverage the data analysis to make concussion therapy even more personalized and predictive. Ideally, she would also like athletes to have access to the tools on a personal device, like a smart phone.

“We want people to have more control over their health and diagnoses,” said LaPlaca. “We want to empower them with information so they can be aware of their health. It would be great if we could turn DETECT into a point of care device that is convenient for athletes, as well as inexpensive.”

LaPlaca finds the brain intriguing and challenging, and every day she leverages her bioengineering background to problem solve for the most efficient, yet complex, machine on earth: the human brain.

Johnna Temenoff is passionate about making people’s lives better. And she does that with her research into regenerative therapies, which involves injecting cells or proteins into tissue to aid healing and stimulate repair. As athletes age and put more stress on their bones, joints and ligaments, degeneration occurs, which leads to tears to the tendons and ligaments. Temenoff is hoping to identify degeneration and stop it in its tracks, before a tear occurs.

“We are trying to better understand what causes the pathology that leads to tears, so we can develop a biomarker or imaging technique to monitor and intervene before the damage occurs,” said Temenoff. “We have a National Institutes of Health (NIH) grant to fund the degeneration research, which is really well suited to athletes who are monitored closely anyways.”

Starting this fall, a new NIH grant will enable Temenoff to focus on the idea of intrinsic healing. She’s proposing an injectable material that would recruit the body’s own stem cells to injured muscle to stimulate regeneration. The cells would then prevent further degeneration and potentially promote future regeneration. Temenoff suspects this research will be very useful for sports injuries like rotator cuff tears, a common condition among athletes born from overuse.

Temenoff’s rotator cuff research has also detected early changes to the cartilage, so she’s looking to target cartilage, as well as tendons for those who may be susceptible to injury. Baseball and football players, swimmers and throwing sports competitors in track and field can benefit from cartilage monitoring. The regenerative therapies being developed would treat the cartilage with an injection, preventing negative changes to the joint.

If a tendon tear does occur, the next question is how best to treat it. Standard procedure is to suture the tendon back to the bone. The biggest issue for athletes in this situation is the inability to return to full function because the muscle is too weak. It is also very easy for re-injury to occur because of the tightness of the tendon. Temenoff has a solution in mind: to completely regenerate the tendon and avoid surgery all together.

“Ideally, we will develop regenerative therapies that mitigate the need for suturing,” said Temenoff. “And our injectable muscle therapy could reduce degeneration in the first place to improve the potential for earlier rehabilitation and return to function.”

Temenoff’s hope is that eventually the regenerative therapies will completely prevent the need for tendon reconstructive surgeries or at least provide alternates to allow the body to regenerate if a tear does occur.

Temenoff is collaborating with Emory Orthopedics and their physician team to validate her studies. The doctors at Emory lend a unique perspective to the research by providing patient tissue samples. Emory also gains an engineering team who is focused on regeneration that they can eventually use to treat their patients. Temenoff expects this synergy to grow as her research continues.

- Georgia Parmelee, Georgia Institute of Technology, College of Engineering

An estimated 120 million people worldwide are infected with lymphatic filariasis, a parasitic, mosquito-borne disease that can cause major swelling and deformity of the legs known as elephantiasis. Health-care workers rely on leg measurements to assess the severity of the condition. However, measuring legs that are severely swollen often proves cumbersome and impractical.

An estimated 120 million people worldwide are infected with lymphatic filariasis, a parasitic, mosquito-borne disease that can cause major swelling and deformity of the legs known as elephantiasis. Health-care workers rely on leg measurements to assess the severity of the condition. However, measuring legs that are severely swollen often proves cumbersome and impractical. An estimated 120 million people worldwide are infected with lymphatic filariasis, a parasitic, mosquito-borne disease that can cause major swelling and deformity of the legs known as elephantiasis. Health-care workers rely on leg measurements to assess the severity of the condition. However, measuring legs that are severely swollen often proves cumbersome and impractical.

An estimated 120 million people worldwide are infected with lymphatic filariasis, a parasitic, mosquito-borne disease that can cause major swelling and deformity of the legs known as elephantiasis. Health-care workers rely on leg measurements to assess the severity of the condition. However, measuring legs that are severely swollen often proves cumbersome and impractical. By combining engineered polymeric materials known as hydrogels with complex intestinal tissue known as organoids – made from human pluripotent stem cells – researchers have taken an important step toward creating a new technology for controlling the growth of these organoids and using them for treating wounds in the gut that can be caused by disorders such as inflammatory bowel disease (IBD).

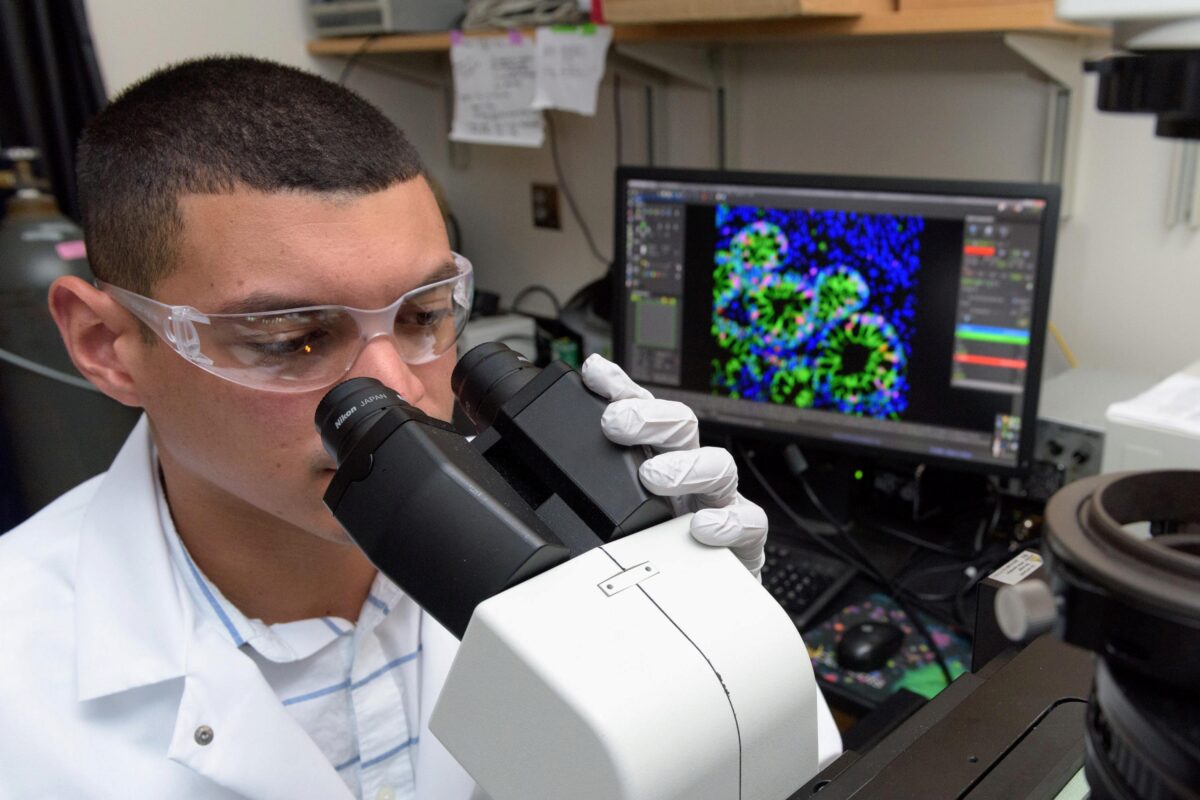

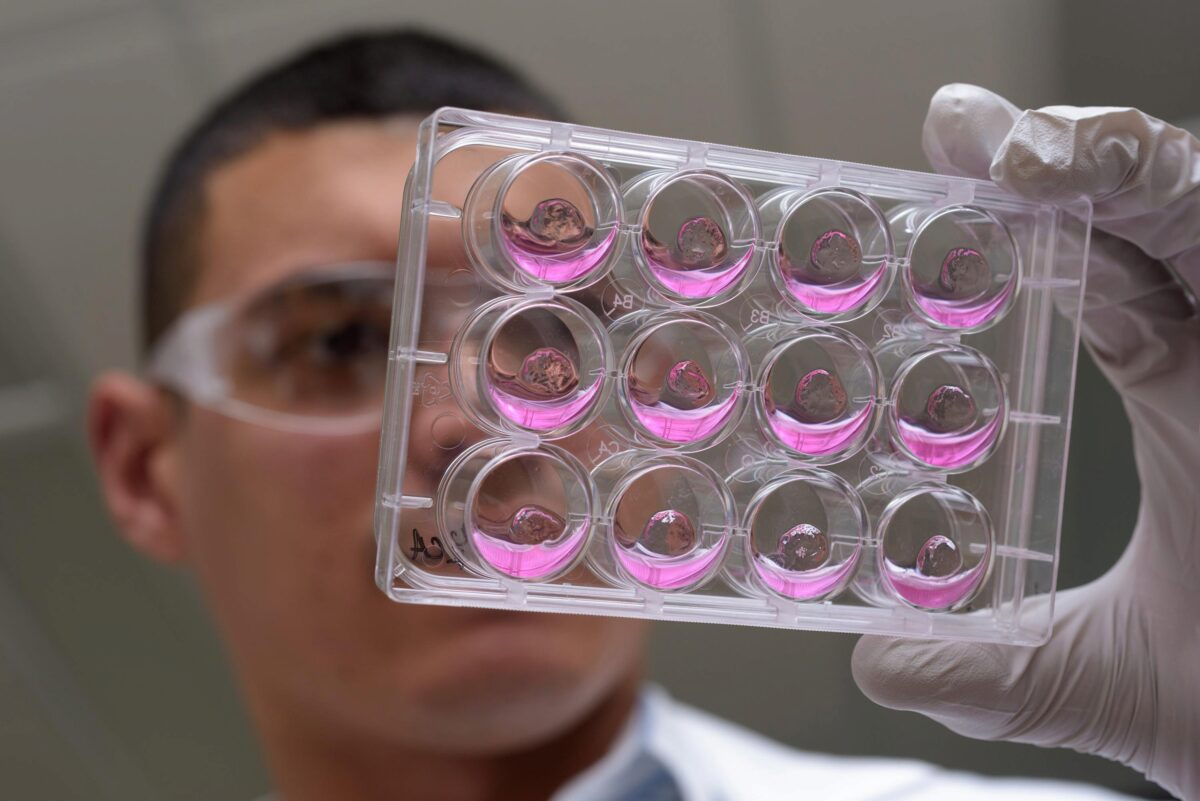

By combining engineered polymeric materials known as hydrogels with complex intestinal tissue known as organoids – made from human pluripotent stem cells – researchers have taken an important step toward creating a new technology for controlling the growth of these organoids and using them for treating wounds in the gut that can be caused by disorders such as inflammatory bowel disease (IBD).  co-lead author in the study. Added Nusrat: “In this work, we demonstrated that the hydrogels facilitate the transplantation of HIOs into an injured intestine, suggesting that this technique has significant implications for treating intestinal injuries caused by diseases such as inflammatory bowel disease.”

co-lead author in the study. Added Nusrat: “In this work, we demonstrated that the hydrogels facilitate the transplantation of HIOs into an injured intestine, suggesting that this technique has significant implications for treating intestinal injuries caused by diseases such as inflammatory bowel disease.”

The purpose of this program is to emphasize the role of communities in the larger quest towards a sustainable energy system. The majority of energy policies are oriented at changing the incentives of individuals, those being people, households or firms, in a way that favors adoption of cleaner technologies or practices, an increase in energy efficiency, or overall reduction in energy consumption. But all those policies and interventions forget the fundamental role that local communities have in fostering an environment in which people’s rewards from adopting those technologies are magnified. It is the role of communities as catalyzers of change that drove me to this research. So as soon as I was invited to co-direct this program, jointly with Matthew Realff (ChBE) and under the close watching eye of SLS Director Jennifer Hirsch, I jump at the opportunity. We have prepared an exciting program and I am looking forward to seeing the results of this engagement.

The purpose of this program is to emphasize the role of communities in the larger quest towards a sustainable energy system. The majority of energy policies are oriented at changing the incentives of individuals, those being people, households or firms, in a way that favors adoption of cleaner technologies or practices, an increase in energy efficiency, or overall reduction in energy consumption. But all those policies and interventions forget the fundamental role that local communities have in fostering an environment in which people’s rewards from adopting those technologies are magnified. It is the role of communities as catalyzers of change that drove me to this research. So as soon as I was invited to co-direct this program, jointly with Matthew Realff (ChBE) and under the close watching eye of SLS Director Jennifer Hirsch, I jump at the opportunity. We have prepared an exciting program and I am looking forward to seeing the results of this engagement. explore that work in the context of the municipality’s efforts to create a livable community. The fellows will also meet in smaller groups to work on their individual projects for the semester related to this topic.

explore that work in the context of the municipality’s efforts to create a livable community. The fellows will also meet in smaller groups to work on their individual projects for the semester related to this topic. He can walk the dog, shoot the moon, or go around the corner. This engineer has an unusual hobby.

He can walk the dog, shoot the moon, or go around the corner. This engineer has an unusual hobby. engineering Ph.D. candidate, works under Tom Kurfess, professor and HUSCO/Ramirez Distinguished Chair in the George W. Woodruff School of Mechanical Engineering, helping manage the Kurfess lab and teaching ME 2110, Creative Decisions and Design. The class focuses on mechanical design and manufacturing, and teaches students to use computer-controlled (CNC) equipment. When the time came to choose an item for students to design and build, Lynn and Kurfess settled on something fun that most students would have a passing familiarity with – a yoyo. With the yoyo design and build, students learn how to use the machines and computer-aided manufacturing software.

engineering Ph.D. candidate, works under Tom Kurfess, professor and HUSCO/Ramirez Distinguished Chair in the George W. Woodruff School of Mechanical Engineering, helping manage the Kurfess lab and teaching ME 2110, Creative Decisions and Design. The class focuses on mechanical design and manufacturing, and teaches students to use computer-controlled (CNC) equipment. When the time came to choose an item for students to design and build, Lynn and Kurfess settled on something fun that most students would have a passing familiarity with – a yoyo. With the yoyo design and build, students learn how to use the machines and computer-aided manufacturing software. Ian Eyre, ME '95, has been a movie daredevil since his undergraduate days at Georgia Tech.

Ian Eyre, ME '95, has been a movie daredevil since his undergraduate days at Georgia Tech. Ten Georgia Tech undergraduates were selected as the inaugural (2017-2018) class of Sustainable Undergraduate Research Fellows (SURF). As paid researchers, they are reviewing, designing, and developing prototypes for interactive systems that will convey the unique elements and qualities of the Kendeda Building for Innovative Sustainable Design (now under construction) and the behaviors that it engenders among its occupants and visitors. The Fellows represent all six colleges at Georgia Tech and were selected from a group of 88 applicants.

Ten Georgia Tech undergraduates were selected as the inaugural (2017-2018) class of Sustainable Undergraduate Research Fellows (SURF). As paid researchers, they are reviewing, designing, and developing prototypes for interactive systems that will convey the unique elements and qualities of the Kendeda Building for Innovative Sustainable Design (now under construction) and the behaviors that it engenders among its occupants and visitors. The Fellows represent all six colleges at Georgia Tech and were selected from a group of 88 applicants.

In today’s highly competitive market, companies must differentiate themselves more than ever before, and for many that means optimizing the customer experience. So it’s no surprise that many of the 136 teams at this year’s fall Capstone Design Expo focused on products and services to improve some aspect of the life of the consumer through innovation.

In today’s highly competitive market, companies must differentiate themselves more than ever before, and for many that means optimizing the customer experience. So it’s no surprise that many of the 136 teams at this year’s fall Capstone Design Expo focused on products and services to improve some aspect of the life of the consumer through innovation.  Tennis elbow, a pulled hamstring, shin splints or an ankle sprain. We’ve all dealt with common sports injuries in an attempt to get in shape. Faculty at Georgia Tech’s College of Engineering are laser focused on providing sports medicine for even the most common injury. Past that, extracellular matrix therapies, regenerative medicine and wearable joint sensory technology are just a few of their more advanced focus areas. Sports medicine today has become a specialized field with many facets. No longer just a study of orthopedics, sports medicine now encompasses new therapies and technologies that tackle all sorts of sports-related injuries and diseases, leveraging predictive analytics and wearables to keep athletes performing at their best.

Tennis elbow, a pulled hamstring, shin splints or an ankle sprain. We’ve all dealt with common sports injuries in an attempt to get in shape. Faculty at Georgia Tech’s College of Engineering are laser focused on providing sports medicine for even the most common injury. Past that, extracellular matrix therapies, regenerative medicine and wearable joint sensory technology are just a few of their more advanced focus areas. Sports medicine today has become a specialized field with many facets. No longer just a study of orthopedics, sports medicine now encompasses new therapies and technologies that tackle all sorts of sports-related injuries and diseases, leveraging predictive analytics and wearables to keep athletes performing at their best.  Originally, when I was applying to be a mechanical engineering student, all I knew was that I liked technology. I played with computers as a kid, and I took autoshop in high school, but I didn’t really have a firm idea of what I wanted to do within engineering. So when it came time to fill out my college application, I filled in the little bubble that sounded coolest.

Originally, when I was applying to be a mechanical engineering student, all I knew was that I liked technology. I played with computers as a kid, and I took autoshop in high school, but I didn’t really have a firm idea of what I wanted to do within engineering. So when it came time to fill out my college application, I filled in the little bubble that sounded coolest.

Woodruff School Assistant Professor Susan Napier Thomas was selected to receive the 2018 Young Investigator Award from the Society for Biomaterials.

Woodruff School Assistant Professor Susan Napier Thomas was selected to receive the 2018 Young Investigator Award from the Society for Biomaterials. Construct3D 2018, the national academic 3D printing and digital fabrication conference and expo, will take place at Georgia Tech on October 5-8, 2018. The second annual event, co-founded by Ultimaker's Lizabeth Arum and Matt Griffin, and Duke University's Chip Bobbert, and sponsored by founding sponsors Ultimaker, and Duke University, will focus on academic use, best practices, and professional development opportunities for faculty, staff, and students from informal, K-12, and higher education contexts.

Construct3D 2018, the national academic 3D printing and digital fabrication conference and expo, will take place at Georgia Tech on October 5-8, 2018. The second annual event, co-founded by Ultimaker's Lizabeth Arum and Matt Griffin, and Duke University's Chip Bobbert, and sponsored by founding sponsors Ultimaker, and Duke University, will focus on academic use, best practices, and professional development opportunities for faculty, staff, and students from informal, K-12, and higher education contexts. New technology that could be used in self-powered smart cities of the future will soon be demonstrated at the NASA Kennedy Space Center’s Visitor Complex at Cape Canaveral, Florida. Ilan Stern, a senior research scientist with the Georgia Tech Research Institute, and colleagues, are collaborating on a $2 million project supported by NASA contractor Delaware North Corporation to build a 40,000-square-foot lighted outdoor footpath demonstrating applications of piezoelectricity for renewable energy.

New technology that could be used in self-powered smart cities of the future will soon be demonstrated at the NASA Kennedy Space Center’s Visitor Complex at Cape Canaveral, Florida. Ilan Stern, a senior research scientist with the Georgia Tech Research Institute, and colleagues, are collaborating on a $2 million project supported by NASA contractor Delaware North Corporation to build a 40,000-square-foot lighted outdoor footpath demonstrating applications of piezoelectricity for renewable energy.